Finite Element Analysis (FEA)

At DPerk Design we focus on quality. Our team is cost effective with a dedication towards excellence in precision and timeliness. We ensure that all results and designs comply with industry standards where applicable and maintain communication with our clients throughout the entire project.

Your FEA Experts

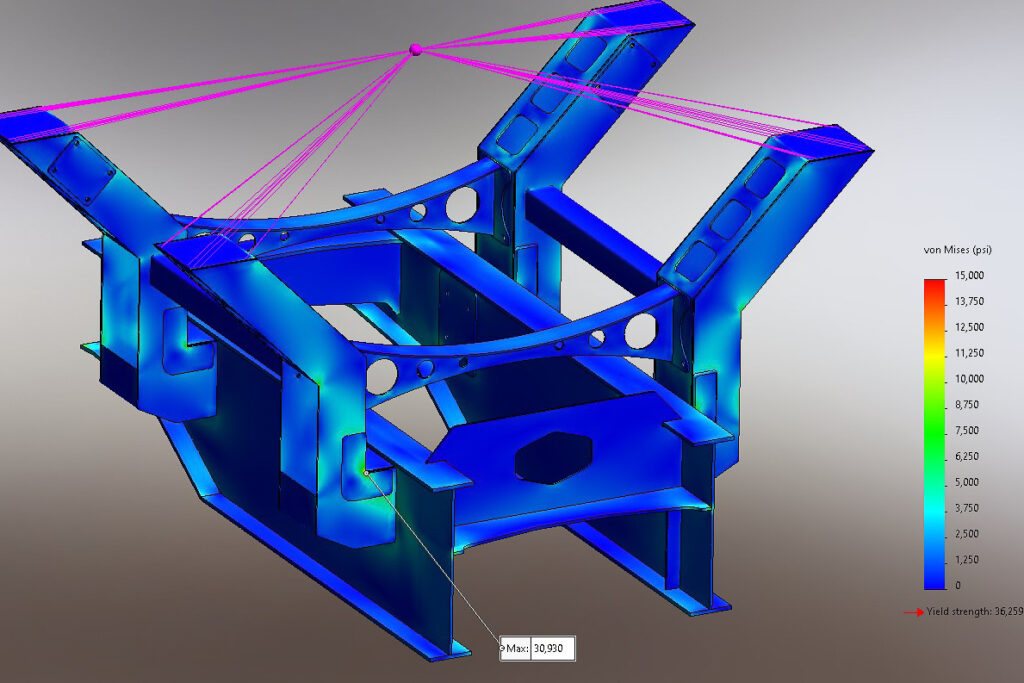

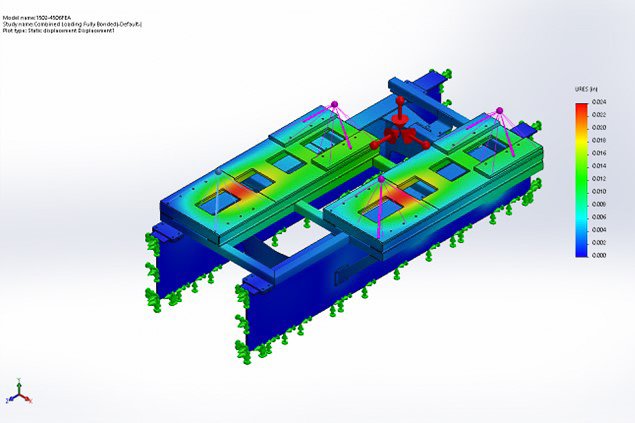

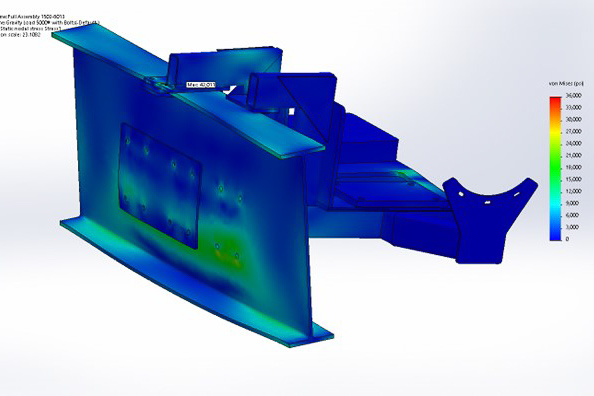

Finite element analysis (FEA) is a computer aided engineering method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow, and other physical effects. Finite element analysis shows whether a product will plastically deform, break, fatigue, or work the way it was designed. In the product development process, it is used to predict what is going to happen when the product is used.

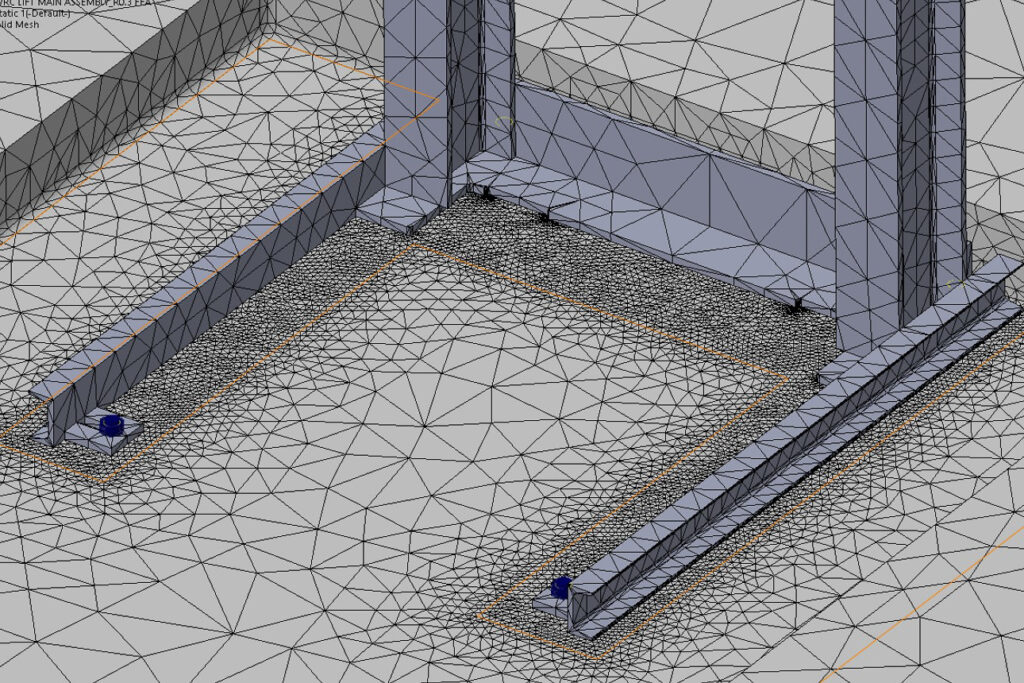

FEA works by breaking down a real object into a large number (thousands to hundreds of thousands) of small elements, such as little cubes or triangles. Mathematical equations help predict the behavior of each element. A computer then adds up all the individual behaviors to predict the behavior of the actual object as a whole.

- Linear Static & Dynamic

- Non-Linear Static & Dynamic

- Transient & Steady State Analysis

- Drop Test

- Plastic Deformation

- Buckling

- Fatigue & Lifetime Predictability

- Vibration

- Harmonic Analysis

Why Choose DPerk Design For Your Next Project?

DPerk Design has a long history of advanced CAE design and simulation experience ranging from a broad spectrum of industries and fields of practice. With over a decade of product design and over 20,000 hours of finite element exposure, no problem is entirely new as a whole and the multi-industry experience brings forth a systematic approach to solving problems. Whether it is a simple design that needs to be verified and presented to upper level management in easy to understand terms or a need to simulate a complex design with static or moving parts via FEA or CFD, DPerk Design has the expertise to deliver accurate results in a timely manner.